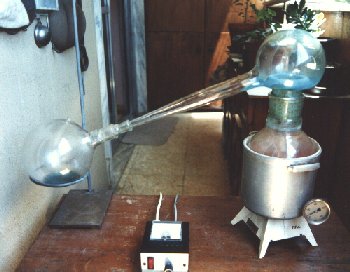

Two or Three Litre Alembic

The alembic is the glassware that is most

important in either the spagyrical or alchemical works. Without this apparel, you cannot

make the spirits that are so important in our Art. Today, it is not easy to find a master

glassmaker that can make an alembic just as the ones used by our old Masters.

In certain cases you can use a copper alembic,

but when it is necessary to make a distillation of acid spirits, the alembic will have to

be of good Pyrex glass.

The 2 or 3 litre retorts are very voluminous and

more difficult to find.

Therefore you will have to seek a master

glassmaker that can manufacture you a glass alembic.

A cucurbit is a balloon of round or conic bottom

known as an Erlenmeyer of 2 or 3 litres with short lap. The helm is a little more

difficult to do. The master glassmaker uses a Pyrex glass spherical balloon and heats it

near the lap and pushes it inside creating like this, a concavity where the condensed

liquids are deposited. For a 3-litre cucurbit, the balloon of the helm should be 1,5

litre.

Then he will adapt a conic tube (horn) of 25 cm

of length in the concavity of the helm so that the condensed liquids deposited in that

concavity can be drained to the exterior. At the tip of that conic tube he makes an

IN19-mm polished male.

At the lap or neck of the helm, an IN45-mm polish

male joint is adapted and in the cucurbit a female joint also of IN45-mm. If the cucurbit

goes of a larger capacity, the polish joint should be of IN70-mm. Most of the times it is

here that the difficulty arises. Because it is necessary to have an appropriate machine to

do these polishing and some artists don't have it.

The receiving vase will be made of a 2 litre

spherical balloon with a short lap and a female polish joint of IN29-mm. Since the beak of

the conic tube (horn) of the helm is a 19-mm joint, an adapter has to be made that allows

the connection among the two. This adapter has a 19-mm female polish on one end and a

29-mm male polish on the other end.

The receiving balloon will have in its belly an

air hole, without which the alembic would explode because of the excess pressure inside.

There are some who say that we are too

conservative in our use of apparels similar to our ancestors, but the truth is that we

have not found yet appropriate substitutes that can make the same work in the necessary

amounts.

He who makes it with conventional apparels is

welcome to tell us the process and the equipment used, because if it is viable it will

save us a lot of money.

The same happens with the circulators or

incubators, which at present are constituted by two vases. The inferior vase can be 1

litre glass Pyrex balloon with round bottom or an Erlenmeyer with female polish of

IN29-mm. The superior vase usually has the half of the capacity of the inferior or 500-ml

with high lap and a polish male of IN29-mm.

The superior vase will have in its top a

capillary air hole to avoid that, with the interior pressure, the superior vase jumps and

breaks. A circulation takes days and sometimes months to do and because of that, it is

convenient to have two or three circulators available.

Also a 500-ml retort with tubulure (horn) will be

indispensable for us to make certain metallic tinctures and the vegetable First Being that

cannot be done in another vase.

Usually in the retort, the beak of the tubular

(horn) doesn't have a male polished end. It is convenient to order one of IN19-mm and

later to use an adapter for the receiving vase that, in this case, can be a 500-ml

spherical balloon with short lap and with a female polished end of IN29-mm with a small

air hole in its belly.

As a source of heat, there are two alternatives.

The more economical ones would be an electric heating mantle or heating plate with a temperature

regulator as used in the chemistry laboratories.

A small gas stove can also be used. In this case

you will have to use an iron pot, enamelled, for a sand bath. Choose a pot sufficiently

large, but not in excess, and put in sifted fine sand and well washed.

Place a layer of sand first in the bottom of the

pot. Then you place the cucurbit in it and after that, you will put the remaining sand so

that it reaches the height of two or three centimetres above the bottom of the cucurbit.

Also it is convenient to place aluminium foil

around the part of the cucurbit that stands out of the pot. This is to prevent the glass

from breaking due to the temperature difference and also to avoid the condensation of

liquids on the walls of the cucurbit and to conduct directly to the helm, all of the

vapour that emanates from the matter.

You will need, also, an appropriate support for

the receiving balloon of the still as used in the chemistry laboratories.

This way, you will have a complete alembic that

will allow you to distil the spirits that will be needed in your works.

The ideal would be that you also have an

identical 6-litre alembic because to distil 50 litres of wine spirit, vinegar or essential

oils of a plant in a 3-litre alembic is not very practical.

Without this apparel, you cannot make the spirits

that are so important in our Art. Today, it is not easy to find a master glassmaker can an

alembic just as ones used by old Masters.

Heaters for 2 Litre Alembics

In relation to the heater for a 2-litre alembic, we

can use, with advantage, a smaller electric frying cooker following the same norms of

assembly as the heater for of 6-litre alembic.

When you acquire the electric frying cooker, take

a 2-litre balloon or Erlenmeyer to verify that it enters easily in the cooker.

You can also opt for the following solution.

Acquire a pot of thick aluminium with an inner diameter of 17 cm and 15 cm of height.

Acquire, also in a store, a 1 kW small portable electric stove without temperature

selector, that is, in preference of the old model, with leg support. The round metallic

box where the refractory ceramic mould is installed with the resistance should not have

more than 13 cm of diameter.

In this stove model, after the upper metallic

part that contains the refractory ceramic mould with the resistance has been dismounted,

it is separated from the metallic support that is the base of the stove. The referred

boxes are fastened together by a screw and nut.

Before dismounting it, disconnect the resistance

wires from the connection terminal, marking its position.

With an electric drill, bore a hole in the bottom

centre of the pot with enough diameters to allow the screw to pass loose.

Then, place the metallic box in the pot,

introducing the screw in the suitable hole and mark the place where the wires will go

through the metallic box that contains the resistance and there, make two holes in the pot

so that those two wires can pass through.

Again, place the box in the pot, in order to

introduce the screw in the central hole and in the metallic support, then take care of

passing the resistance wires through the opened holes in the pot.

Holding with one hand the metallic box with the

refractory and the resistance, place a washer on the screw and tighten the screw to the

suitable nut. Be sure to verify if the wires of the resistance are in position to be

tighten to the screw of the connection plate.

Tighten the nut in that position. Check that the

wires coming out of the metallic box are well insulated, that is, that the insulation

covers the wires completely and have not been damaged.

Wrap the wire's end to the suitable screws

as they were previously and tighten the nuts. Verify that the wires are not leaning

against the support or the pot. Verify, also, if the electric cable that came with the

stove is connected in the same place as it was previously.

Place the lower cover on the metallic support and

tighten the fixation screw. The heater will be ready.

Rubellus Petrinus